| Availability: | |

|---|---|

| Quantity: | |

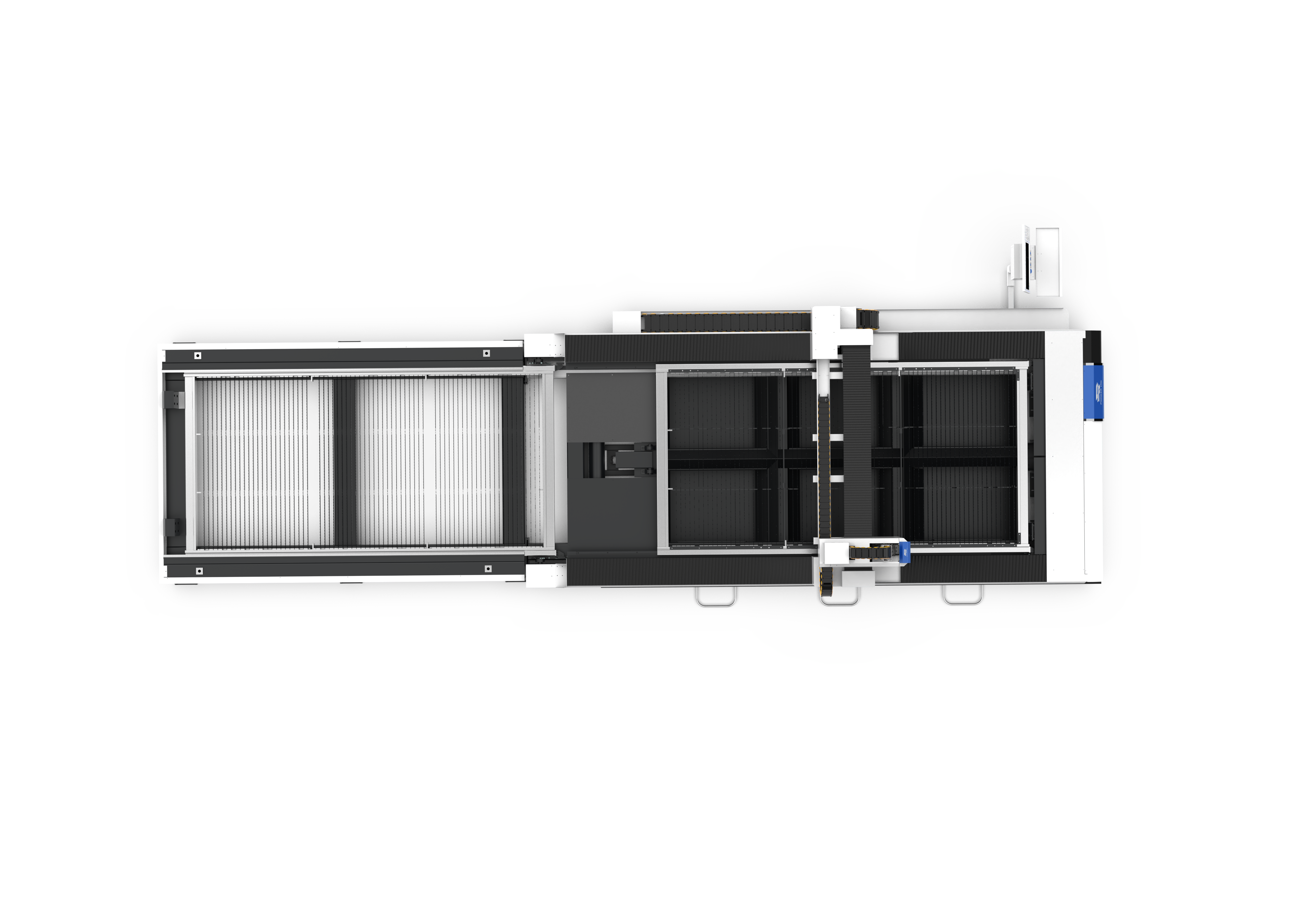

The Custom High-Power Exchange Fiber Laser Cutting Machine for Stainless Steel from Jinan Pioneer CNC Technology is designed for precise and efficient metal cutting. This machine offers a cutting range of 3000mm x 1500mm, making it ideal for a variety of applications in industries such as automotive, aerospace, and metal fabrication.

With a laser power range from 1000W to 6000W, it can handle a wide range of materials, offering versatility in cutting thickness and speed. The maximum workbench load is 1200KG, ensuring heavy-duty operations.

The automatic/manual focus feature ensures precise cutting even for varying material thicknesses. With high-speed cutting capabilities, the machine can reach speeds of up to 132m/min, enhancing productivity. The maximum G-speed of 1.5G ensures a fast response time and minimal downtime.

The positioning accuracy of ±0.03mm/m and repeat positioning accuracy of ±0.02mm/m ensure high precision, reducing errors and ensuring consistent results. The robust design of the machine, including a large dimension of 8380mm * 2430mm * 1800mm, ensures stability and long-lasting performance.

This fiber laser cutting machine is highly suitable for metal sheet cutting, custom cutting applications, and industrial metal fabrication. It is available for sale, and aftermarket services are provided by reliable suppliers.

| Parameter | Value |

|---|---|

| Model | PF-3015H |

| Processing Range (L x W) | 3000mm x 1500mm |

| Laser Power | 1000W - 6000W |

| Workbench Maximum Load | 1200KG |

| Positioning Accuracy | ±0.03mm/m |

| Repeat Positioning Accuracy | ±0.02mm/m |

| Maximum Speed | 132m/min |

| Maximum G Speed | 1.5G |

| Dimensions | 8380mm x 2430mm x 1800mm |

| Focusing Method | Automatic/Manual |

High-speed cutting: Provides fast cutting, hole-making, and graphic cutting to boost production efficiency.

Double worktable automatic exchange: Enables simultaneous feeding and cutting, significantly increasing overall cutting speed.

Quality bed structure: Aircraft metal honeycomb structure ensures high strength and cutting precision.

High and low switch plate: Rapid platform exchange reduces loading and unloading time, improving efficiency.

Aviation aluminum extruded beam: The beam is lightweight, rigid, and resistant to deformation, ensuring dynamic performance.

Swiss Raytools Laser Head: Features modular design with anti-crash function, dual water cooling, and auto-focus for precise cutting.

Automatic lubrication system: Ensures smooth operation with automatic lubrication for the rails and racks.

Auto-focus laser head: Adjusts the laser head to follow the material height, ensuring consistent cutting despite material irregularities.

Thick-walled carbon steel welded bed: High-quality carbon steel welded bed provides better stability and durability than ordinary tube welded beds.

Stable and Efficient Operation: The machine offers high responsiveness, power, and stability, ensuring faster cutting and improved efficiency.

Increased Production Efficiency: Double worktable automatic exchange and faster cutting speeds improve overall productivity.

Reduced Labor Costs: The high and low switch plate system minimizes time spent on loading and unloading, saving labor costs.

Durability and Precision: Aircraft-grade materials and advanced software ensure precise cutting results and long-term stable performance.

Billboards and Advertising: Ideal for cutting signs, signage, LED letters, and metal letters for advertising purposes.

Sheet Metal Processing: Perfect for cutting sheet metal, ironware, chassis, and racks used in various industries.

Metal Components: Designed for cutting parts like auto parts, elevator panels, and metal art for industrial applications.

Industrial Applications: Suitable for producing kitchenware, electronic parts, glasses frames, and nameplates, among other products.

What is the cutting capacity of the custom high-power exchange fiber laser cutting machine?

The machine supports laser power ranging from 1000W to 6000W and can handle a variety of metal thicknesses.

What materials can be cut with the fiber laser cutting machine?

This machine is ideal for cutting stainless steel, carbon steel, aluminum, copper, brass, and other metals.

How does the exchange platform improve efficiency?

The double worktable automatic exchange allows for simultaneous feeding and cutting, reducing idle time and improving overall production efficiency.

What are the advantages of using a high-power fiber laser cutting machine?

Higher power allows for faster cutting speeds and improved precision, making it ideal for heavy-duty applications and high-volume production.

Is this machine customizable?

Yes, we provide custom solutions tailored to your specific needs, including laser power, work area, and other features.